In precision engineering and design, Billet Technology is an art form that seamlessly blends functionality and aesthetics. This innovative manufacturing process has gained immense popularity across diverse industries owing to its exceptional precision, versatility, and unique visual appeal. In this article, we embark on a journey to explore the world of Technology Billet, unraveling its definition, applications, benefits, and potential future trends.

Billet Engineering is more than just a manufacturing technique; it represents a convergence of artistry and engineering excellence. The precise craftsmanship and meticulous attention to detail involved in this process result in products that perform flawlessly and exude a sense of luxury and sophistication. By exploring the foundations and applications of Billet Technology, we aim to shed light on how this artful precision engineering has revolutionized various industries.

What is Billet Technology?

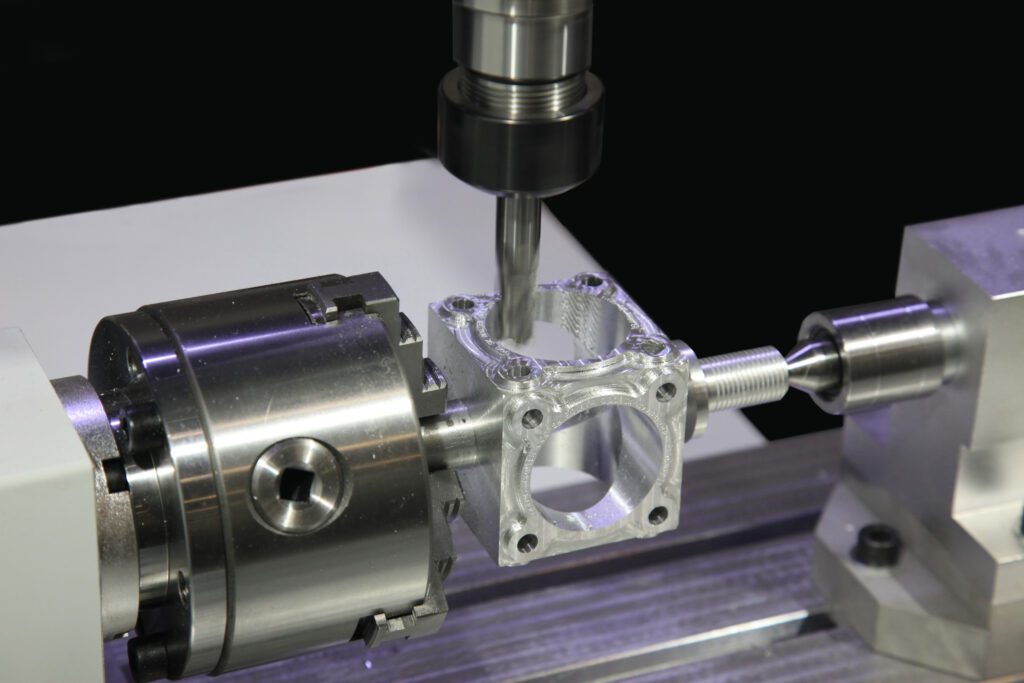

Billet Technology, also known as CNC Billet Machining, is a sophisticated manufacturing process that involves shaping a solid block of metal, referred to as a billet, into intricate and precise components using Computer Numerical Control (CNC) machines. This subtractive manufacturing technique empowers engineers and designers to create custom parts and products with unrivaled precision and accuracy.

The process begins with a solid block of metal, commonly aluminum, brass, or stainless steel, known as a billet. The billet is secured in the CNC machine, where it undergoes precise cutting and shaping according to digital blueprints and computer instructions. This automated process ensures that the final product meets exact specifications, with tolerances as tight as a few thousandths of an inch. The result is a meticulously crafted component that exhibits exceptional structural integrity, functionality, and aesthetic appeal.

The Craftsmanship Behind Billet Technology

At the core of Technology Billet lies craftsmanship and expertise. Highly skilled machinists harness the power of CNC machines to sculpt intricate designs and shapes from a solid piece of metal. The process demands meticulous attention to detail, as even the slightest deviation can impact the final product’s performance and aesthetics. The dedication and artistry of these craftsmen elevate Technology for Billet to a league of its own, setting it apart from conventional manufacturing methods.

The process of Billet Technology requires a deep understanding of materials, machining techniques, and design principles. Machinists meticulously set up the CNC machines and fine-tune the cutting parameters to achieve precise results. Each process step is executed meticulously, ensuring every cut and contour aligns perfectly with the design specifications. The final product is a testament to the skill and expertise of the artisans, showcasing the seamless fusion of engineering precision and artistic finesse.

Applications of Billet Technology

The versatility of Billet Technology opens doors to a myriad of applications across various industries. Across multiple industries, including automotive, aerospace, consumer electronics, and beyond, this pioneering manufacturing process enables the production of an extensive array of products, encompassing engine components, chassis parts, and high-performance electronic devices.

Billet Innovation has revolutionized the design and manufacturing of engine components, suspension parts, and custom accessories in the automotive industry. Using Billet Engineering, automotive enthusiasts can personalize their vehicles with precision-crafted pieces that enhance performance and add a touch of elegance to their prized possessions.

Billet Technology is pivotal in producing critical flight components and aerospace structural parts in the aerospace sector, where safety and performance are paramount. The process ensures that every element meets stringent quality standards and adheres to precise engineering specifications, making it an indispensable manufacturing method in the aerospace industry.

Consumer electronics have also embraced Billet Technology to elevate product design and functionality. From smartphone frames to laptop casings and audio equipment, manufacturers leverage Technology Billet to create sleek and durable electronic devices that resonate with consumers seeking style and substance.

Moreover, Billet Technology finds applications in marine and industrial settings, where the demand for robust and high-performing components is paramount. With its remarkable adaptability, this manufacturing process emerges as the ideal choice for precision engineering, capable of accommodating the diverse requirements of various industries and becoming their preferred option.

Advantages and Benefits of Using Billet Technology

The adoption of Billet Engineering presents numerous advantages. One of its primary benefits is its exceptional precision, ensuring that components meet exact specifications. The process also yields parts with high strength, durability, and reliability. Billet Innovation also allows for the creation of intricate designs and shapes that may be unachievable with other manufacturing methods. Furthermore, the reduced material waste during the machining process contributes to sustainability, making Technology Billet an environmentally conscious choice.

Unlike traditional manufacturing methods, such as casting and forging, Technology for Billet offers several distinct advantages. The process allows for tighter tolerances, resulting in components with exceptional dimensional accuracy. This level of precision translates into better performance, reduced wear and tear, and improved overall efficiency of the end products.

Moreover, Billet Technology empowers designers and engineers with greater design flexibility. The CNC machining process can create intricate and complex shapes that enhance the functionality and aesthetics of the components. This design freedom enables the creation of custom features tailored to specific applications, leading to products that perform optimally in their intended use cases.

The high strength and durability of Technology Billet components make them well-suited for demanding applications. Whether it’s high-performance automotive parts, critical aerospace components, or rugged industrial equipment, Technology Billet ensures that the end products meet the rigorous demands of their respective industries.

Furthermore, Billet Technology’s reduced material waste contributes to sustainable manufacturing practices. By precisely shaping components from solid metal blocks, minimal material is left unused. Consequently, the overall environmental impact is reduced, and production costs are lowered, rendering it a financially sustainable option for the long term.

The Versatility of Billet Technology

Technology for Billet’s adaptability significantly contributes to its widespread use across diverse industries. The process can cater to the unique requirements of different sectors, from automotive to aerospace and even consumer electronics. Whether crafting precision engine parts or creating stylish and high-performing electronic devices, Billet Technology effortlessly rises to the challenge.

In the automotive industry, Billet Innovation enables the production of custom parts and accessories that cater to the unique tastes of car enthusiasts. Engine components, suspension parts, and custom grilles are just a few examples of how Billet Innovation adds a touch of personalization to vehicles, enhancing both performance and aesthetics.

In the aerospace sector, Billet Technology’s precision and reliability are crucial in ensuring the safety and performance of flight components. Every component must meet strict quality standards, from aircraft landing gear to critical engine parts, and Technology Billet delivers on those requirements with exceptional precision.

The consumer electronics industry leverages Technology Billet to create products that captivate consumers with their design and functionality. Smartphones, laptops, and audio equipment benefit from the enhanced durability and sleek aesthetics of Billet Technology, providing consumers with high-quality and visually appealing electronic devices.

Moreover, the marine industry relies on Billet Innovation to manufacture rugged and durable components for vessels and marine equipment. Whether it’s marine engine parts or navigational equipment, Technology for Billet’s precision and strength are instrumental in ensuring the smooth operation of marine vessels.

Additionally, Billet Technology finds applications in industrial settings where robust and high-performing components are essential. Industrial equipment, machinery, and tooling all benefit from the precision and durability of Technology Billet, ensuring reliable and efficient operation in demanding industrial environments.

Billet Technology in Automotive Engineering

Billet Technology plays a pivotal role in creating high-performance parts and accessories in the automotive industry. Manufacturers leverage their precision and durability to craft custom engine, transmission, and suspension components. Billet Innovation also allows for the creation of visually striking grilles, shift knobs, and other automotive accessories embodying style and functionality.

The automotive industry’s constant pursuit of improved performance and individuality finds a perfect match in Technology Billet. Enthusiasts and performance-focused drivers seek components that deliver on performance and make a visual statement. Billet Technology offers the means to achieve both objectives, enabling car owners to personalize their vehicles with precision-crafted parts that elevate the driving experience.

Engine components, such as cylinder heads, connecting rods, and camshafts, benefit significantly from the precision and strength imparted by Billet Engineering. These components operate under extreme conditions, and their performance directly impacts the overall engine’s power and efficiency. Technology for Billet enables manufacturers to craft engine parts that consistently meet the most stringent quality and reliability criteria.

In addition to enhancing engine performance, Billet Technology’s visual appeal makes it a preferred choice for crafting automotive accessories. Grilles, emblems, and interior accents crafted through Billet Innovation add a touch of luxury and exclusivity to vehicles, reflecting the owner’s style and taste.

Moreover, Technology Billet allows for the creation of custom suspension components, improving the vehicle’s handling and ride comfort. Whether it’s sway bars, control arms, or strut mounts, these precision-crafted parts contribute to a more engaging driving experience, making Billet Technology an integral part of the automotive performance enhancement landscape.

Billet Technology in Aerospace Industry

The aerospace sector demands components of utmost precision and reliability. Billet Technology meets these demands by providing a manufacturing process that yields parts with uncompromising accuracy and structural integrity. Billet Innovation ensures the highest quality and performance, from critical flight components to aerospace structural parts.

Aircraft, spacecraft, and other aerospace vehicles operate in environments where safety and reliability are paramount. Every component used in aerospace applications must undergo rigorous testing and meet stringent quality standards. Technology Billet plays a crucial role in achieving these standards, producing exceptional precision and consistency components.

Billet Technology manufactures various flight-critical components in aerospace engineering, such as landing gear parts, engine components, and structural elements. These components must withstand the stresses of flight, temperature fluctuations, and other challenging conditions. The precision and high strength of parts crafted through Billet Engineering contribute to aerospace vehicles’ overall safety and performance.

Moreover, the aerospace industry strongly emphasizes weight reduction to improve fuel efficiency and overall performance. Billet Technology allows for the creation of lightweight yet robust components, helping aerospace manufacturers strike the right balance between strength and weight savings.

Furthermore, the aerospace sector often requires custom components tailored to specific missions or applications. Technology for Billet’s design flexibility enables the production of bespoke parts that meet the unique needs of each aerospace project. From one-off prototypes to small production runs, Billet Innovation offers an efficient and reliable solution for aerospace component manufacturing.

Billet Technology in Consumer Electronics

In the world of consumer electronics, aesthetics, and functionality are paramount. Billet Technology offers designers the freedom to create visually appealing and high-performing devices. From smartphone frames to laptop casings and audio equipment, Technology Billet enhances consumer electronic products’ design and structural integrity, elevating the overall user experience.

Consumer electronics manufacturers seek to create products that impress with their performance and captivate consumers with their designs. Billet Technology’s precision machining process allows for the creation of sleek and stylish product enclosures that resonate with tech-savvy consumers seeking premium experiences.

The frame and chassis provide structural support in smartphones and house critical internal components. Billet Technology’s CNC machining process ensures that smartphone frames are precisely crafted to accommodate the device’s features with an exact fit, contributing to the overall device’s slim and elegant design.

Similarly, laptop casings benefit from Technology Billet’s precision, resulting in thin, lightweight, yet durable enclosures. The precise machining of laptop casings also aids in better thermal management, ensuring that the device operates optimally under various workloads.

Moreover, audio equipment, such as high-quality headphones and speakers, benefit from the enhanced performance and aesthetics achieved through Billet Technology. The precision shaping of components ensures optimal sound quality and durability, enhancing the overall audio experience for consumers.

Additionally, Billet Innovation offers design flexibility, enabling the creation of custom components for niche or specialized electronic devices. From medical equipment to wearable technology, Billet Technology adapts to the unique requirements of each product category, providing manufacturers with a reliable and efficient manufacturing solution.

Sustainability and Billet Technology

Sustainability is a crucial consideration in modern manufacturing practices. Billet Technology contributes to sustainable practices by reducing material waste. The process utilizes CNC machines to shape components precisely, minimizing the need for excess materials. This approach mitigates the overall environmental impact while production costs are simultaneously reduced, establishing it as a financially sound choice for the long term.

Traditional manufacturing methods, such as casting and forging, often generate substantial material waste. Large quantities of raw materials are required to cast molds or create dies, resulting in significant leftover materials that are usually discarded. Billet Technology eliminates the need for molds and dies, as components are directly shaped from solid metal billets. The CNC machining process precisely cuts and shapes the elements, leaving minimal material waste.

Furthermore, reduced material waste has a positive effect on the environmental footprint of manufacturing. Technology Billet conserves natural resources and reduces energy consumption during the manufacturing process by using only the necessary materials.

Additionally, Technology for Billet’s design flexibility allows for the creation of custom components tailored to specific applications. This personalized approach ensures features are optimized for their intended use, avoiding unnecessary material usage.

Moreover, the longevity and durability of Billet Technology components contribute to sustainable consumption. By creating parts that withstand wear and tear, Billet Engineering reduces the frequency of replacements, thus decreasing the overall demand for new components.

The focus on sustainability in manufacturing practices aligns with the global movement towards a more eco-friendly and resource-efficient future. As industries prioritize sustainable practices, Billet Technology stands out as a responsible and forward-thinking manufacturing method.

Future Trends in Billet Technology

Billet Technology is poised for further growth and refinement as technology and innovation continue to advance. Advancements in CNC machining, material options, and design capabilities are expected to drive the continued evolution of this manufacturing process. Moreover, the ever-expanding applications of Billet Engineering across industries signal a promising future for this artful precision engineering method.

The evolution and advancement of CNC machining technology are set to exert a meaningful influence on shaping the future of Billet Technology.

Improvements in machining precision and efficiency will enable manufacturers to create even more intricate and complex designs. Furthermore, advances in multi-axis CNC machines will enhance the complexity achieved in component design, allowing for highly sophisticated shapes and contours.

Additionally, Technology Billet is expected to explore new materials and alloys to meet the demands of emerging industries and applications. Integrating advanced materials, such as composites and lightweight alloys, will further enhance the performance and capabilities of components crafted through Billet Technology.

Design optimization and simulation tools will become instrumental in the future of Billet Technology. Computer simulations will allow engineers to analyze components’ structural integrity and performance virtually before machining. This process will lead to more efficient and precise design iterations, saving time and resources in the manufacturing process.

The growing focus on sustainability in manufacturing will drive the adoption of Billet Technology as an eco-friendly manufacturing method. Its ability to reduce material waste and energy consumption aligns intending to create environmentally responsible products and processes.

Moreover, Technology for Billet’s application in rapid prototyping will become more prevalent. As industries seek to shorten product development cycles, Billet Technology’s CNC machining process offers a quick and accurate method for efficiently producing prototypes and iterating designs.

As industries continue to explore new applications for Billet Technology, the scope of its versatility will expand further. From medical devices to renewable energy components, Billet Technology will continue to find new and innovative uses in various sectors, solidifying its position as a transformative force in precision engineering.

Conclusion

Billet Technology is a remarkable fusion of art and engineering, where precision and style converge to create extraordinary components and products. Its versatility and ability to cater to diverse industries make it a preferred choice for crafting complex, high-performance parts. As technology continues to evolve, Billet Technology will undoubtedly remain at the forefront of precision engineering, shaping industries and products with artful precision.

The art of Billet Technology, where raw materials are sculpted into exquisite components through precise machining, showcases the pinnacle of human craftsmanship and engineering excellence. From automotive and aerospace applications to consumer electronics and industrial equipment, Billet Engineering leaves its mark on many products, elevating their performance and aesthetics.

In an ever-evolving manufacturing landscape, Billet Technology is a testament to the power of precision engineering and the pursuit of excellence. Its journey has just begun, and the future holds exciting possibilities as technology advances and industries embrace this artful precision engineering method.

FAQs (Frequently Asked Questions)

Q.Is Billet Technology suitable for small-scale production?

A .Absolutely, Technology Billet can accommodate both small-scale and large-scale production requirements. Its adaptability enables manufacturers to efficiently create custom components in varying quantities, making it a viable option for diverse production needs.

Q.How does Billet Technology compare to other manufacturing methods?

A. Billet Technology offers several distinct advantages over traditional manufacturing methods. Its exceptional precision, improved strength, and design flexibility set it apart. Additionally, the ability to work with various materials and create intricate shapes makes Technology Billet a superior choice for precision engineering.

Q.Which industries benefit most from Billet Technology?

A. Billet Innovation finds extensive applications in numerous industries. Automotive, aerospace, consumer electronics, and marine industries are among the sectors that benefit significantly from this precision manufacturing technique.

Q.Is Billet Technology environmentally friendly?

A. Billet Engineering contributes to sustainability by minimizing material waste and energy consumption. The precision machining process reduces the need for excess materials, making it an environmentally friendly option compared to conventional manufacturing methods.

Q. Can Billet Technology be used for rapid prototyping?

A. Absolutely, Technology Billet is suitable for rapid prototyping. The CNC machining process allows for quick and accurate production of prototypes, facilitating efficient testing and iteration of designs for various applications.